Better Touch Better Business

Contact Sales at Ruian Lead.

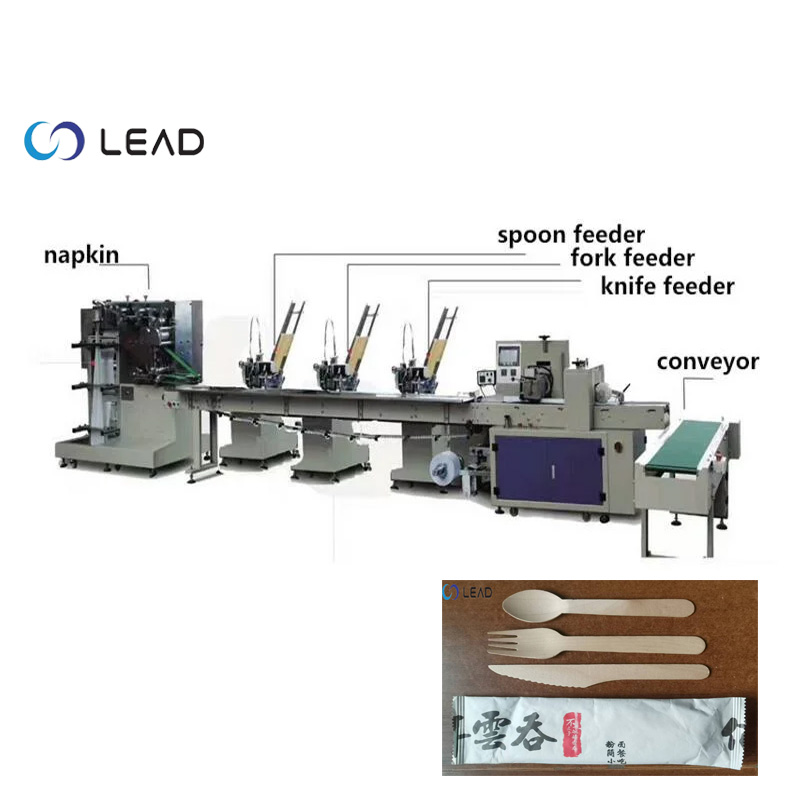

Automatic packaging machine manufacturers Lead Machinery specialized in the development and manufacture of best cutlery wrapping machine

Our main series products are based on flow packing machine. And extend to various automatic feeding solution.

In today's fast-paced world, automation has become crucial in various industries to ensure efficiency, cost-effectiveness and precision. The manufacturing process of tableware automatic packaging machine is no exception. This article aims to delve into the intricacies of this process, highlighting the key steps involved and highlighting its impact on increasing productivity in the tableware industry.

1. Design and development:

The first step in manufacturing an automatic cutlery packaging machine is the design and development of the machine itself. This process involves a team of skilled engineers who collaborate to create designs that meet industry-specific requirements. Factors they consider include the type of tableware to be packaged, the required packaging efficiency, and the overall functionality of the machine.The design phase is followed by the development of prototypes, which are then thoroughly tested for functionality, durability and safety. Feedback from these tests is used to further refine the machine's design.

2. Material selection:

Choosing the right material is critical to ensuring the durability and reliability of your packaging machine. High-quality metals such as stainless steel are often used for racks because they are durable and resistant to corrosion. Other components, such as gears, belts and motors, need to be carefully selected to ensure they can withstand the rigors of continuous operation.

3. Assembly and integration:

The next stage involves the assembly and integration of the various components into a fully functional automatic packaging machine. Skilled technicians carefully follow assembly instructions and make precise adjustments to ensure proper alignment and smooth operation. This stage is critical as any errors in assembly can lead to failure or inefficiency.

Additionally, the integration of software and programmable logic controllers (PLCs) is critical to the automation of the packaging process. These systems enable machines to operate seamlessly by controlling the movement, timing and synchronization of different components.

4. Quality assurance and testing:

Once the machines are assembled, a comprehensive quality assurance process is put in place to ensure they meet high standards. This involves rigorous testing of various functional and performance parameters such as speed, accuracy and reliability. In addition, safety features have been thoroughly checked and obtained the necessary certifications to comply with industry regulations.

5. Installation and maintenance:

After passing all quality tests, the automatic packaging machine is ready to be installed in the customer's factory. Experienced technicians oversee the installation process, ensuring proper calibration and meeting any initial setup requirements. They also provide training to their customers' operators on how to operate and maintain their machines efficiently.

Additionally, a regular maintenance schedule is in place to keep the machine running smoothly and prevent unexpected breakdowns. Manufacturers often provide after-sales service and support to ensure the long-term reliability of automatic tableware packaging machines.

The manufacturing process of the tableware automatic packaging machine involves a careful combination of design, material selection, assembly and testing. The process culminates in a sophisticated machine that increases productivity and seamlessness in the cutlery industry. By automating the packaging process, manufacturers can increase efficiency, reduce labor costs and maintain consistent quality of the final product. With continuous advancements in automation technology, tableware manufacturers can rely on these innovative machines to efficiently meet the growing demands of the market.

Lead Machinery, a professional packing machine manufacturer, so far, our tableware packaging machines have been exported to more than 20 countries around the world, and are deeply loved by customers. If you want to know more about the machine, please contact us.

Copyright©2020Ruian Lead Machinery & Technology Co., Ltd.| All Rights Reserved