Automatic packaging machine manufacturers Lead Machinery specialized in the development and manufacture of best cutlery wrapping machine

Lead Machinery custom wet tissue packaging machine supply for life

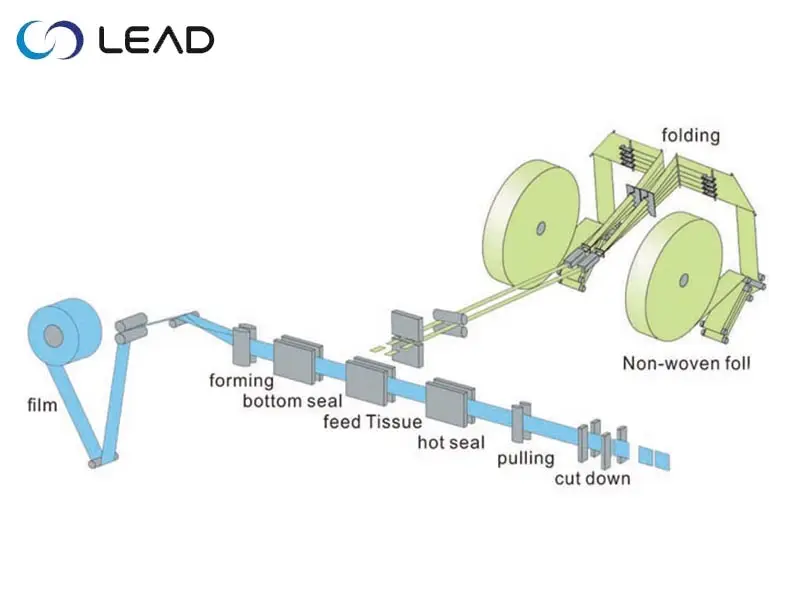

A wet tissue packaging machine is a type of machinery that packages tissue paper products such as facial tissues, toilet paper, paper towels, and napkins. In tissue paper manufacturing plants, these machines are used to package tissue products consistently and efficiently.

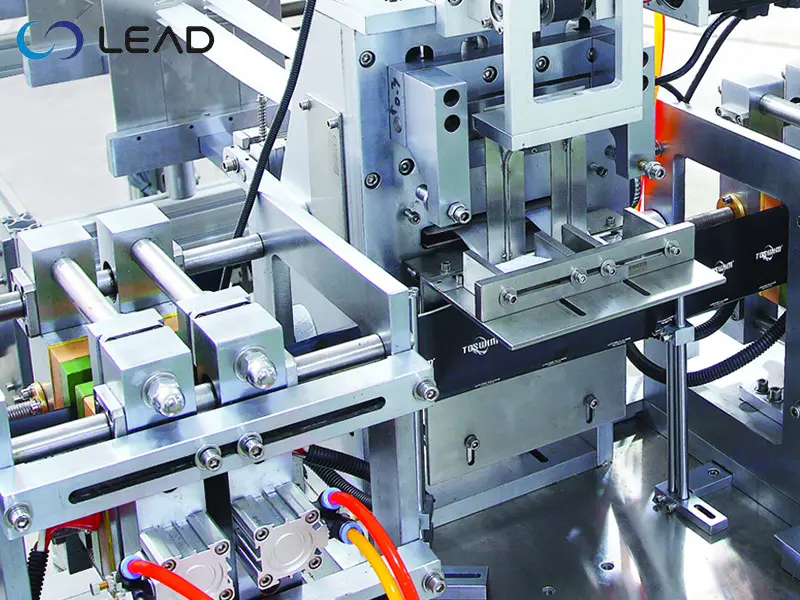

The wet tissue packaging equipment machine typically consists of a series of conveyor belts and rollers that move the tissue products through the machine. Depending on the packaging format desired, the machine can fold, wrap, and seal tissue products in various configurations.

Other wet tissue packaging machines are semi-automated or manual, with operators handling some or all of the packaging steps. Some are fully automated with computer controls and sensors that monitor the packaging process.

A range of sizes and configurations are available to accommodate different types and sizes of wet tissue products in the tissue paper manufacturing industry. Wet tissue packaging machines can increase efficiency, reduce labor costs, and improve product quality.

We make use of guaranteed raw material that is procured for trusted vendors to guarantee the quality of this product.

Benefit of wet tissue packaging machine:

There are several benefits of using a wet tissue packing machine in the tissue paper manufacturing process, including:

Improved Efficiency: Tissue packaging machines can package tissue products at a much faster rate than manual packaging methods, which helps to increase overall production efficiency.

Cost Savings: By automating the packaging process, wet tissue machinery can help to reduce labor costs and increase productivity, which can result in cost savings for tissue paper manufacturers.

Increased Productivity: Wet tissue packing machines can operate continuously, 24/7, without breaks or downtime, which helps to maximize productivity and output.

Reduced Waste: Wet tssue manufacturing machines are designed to minimize waste by using the correct amount of packaging materials for each product, which helps to reduce material costs and environmental impact.

Product Quality: Tissue packaging machines are designed to produce consistent packaging quality, which ensures that every product is properly packaged and meets quality standards.

Overall, the use of a wet tissue packaging machine can help wet wipes machine manufacturers to improve efficiency, increase productivity, reduce costs, and maintain consistent product quality.

| Model: | LD-WT250 |

|---|---|

| MOQ: | 1 set |

| Payment: | L/C,T/T |

| Place of Origin: | Zhejiang China |

| Brand: | LEAD |

| Delivery Time: | 7 - 20 days |

Application of wet tissue packaging machine:

Packaging napkin products such as dinner napkins, luncheon napkins, and beverage napkins can be done with wet tissue packaging machines.

In the packaging of facial tissue products, such as tissues in box, pocket tissues, and interfolded tissues, tissue packaging machines are commonly used.

Rolls, jumbo rolls, and coreless rolls of toilet tissue are also packaged with tissue packaging machines.

Packaging paper towels: Wet tissue packaging machines are used to package folded paper towels, interfolded paper towels, and rolls of paper towels.

Non-woven tissues, medical tissue products, and wet wipes can also be packaged using tissue packaging machines.

Wet tissue packaging machines can also be customized to meet the specific needs of wet tissue paper manufacturers, including product size, packaging format, and output capacity.

Better connections, better business

Mobile/Whatsapp/WeChat