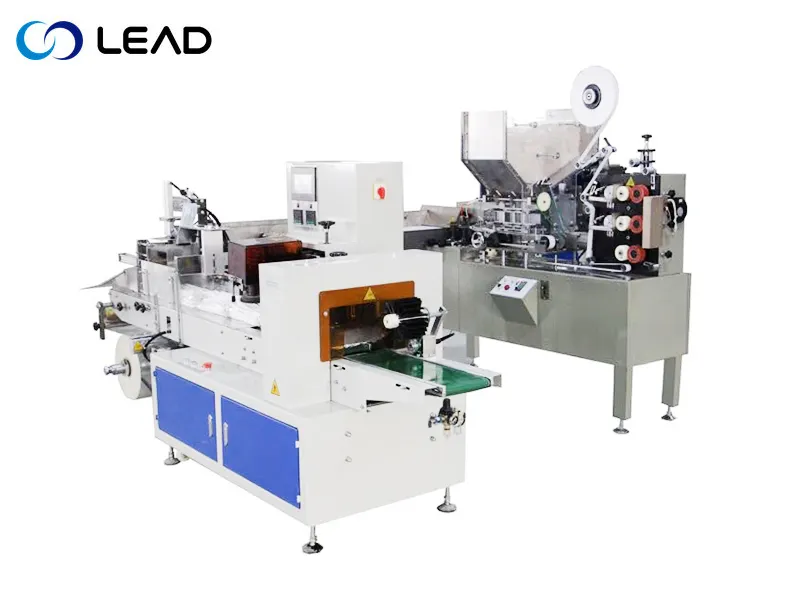

Automatic packaging machine manufacturers Lead Machinery specialized in the development and manufacture of best cutlery wrapping machine

Lead machinery top paper bags packaging machine market manufacturers for toothpick

The product is notable for its high energy efficiency. This product consumes little energy or power to finish its task.

Lead automatic toothpick packing machine specializing in the production of paper based toothpick packing machine, it has a high speed. High efficiency. Good stability. Can be single and double support. Single and double head. Packaging paper thickness required Min. 28 grams to 100 grams. OPP film also available. Packaging is fully automated.

The Automatic Paper Bag Toothpick Packing Machine is suitable for packaging toothpicks, chopsticks, bamboo sticks, and can also print logo on the paper bag, and the speed can be adjusted as needed.

This toothpick wrapping machine is used for packing chopsticks or toothpicks into paper bag automatically. It has advantages of : Speed controlled by frequency inverter, feeding chopsticks, cutting ,sealing and counting automatically.

Paper wrapped toothpick packing machine is high frequency, which adopted water character ink printing by flexographic plate, and able to print two color in two sides. The length of the chopsticks depends on customers’ requirement.

This paper wrapped toothpick packaging machine is a packaging machine can packaging pearl film, PE, OPP, POF can be heated film material. The upgrading of the original models, the use of smart thermostat control, good packaging. (Toothpicks packing machine can be customized)

Main Features of Automatic toothpick manufacturing equipment:

1.Two-color printing function.

Auto gluing, counting and drying.

Three-side sealing with embossing sel.

Suitable for packaging paper, PE coated paper or plastic film.

One bag one or two toothpicks

2.Speed is shifted by step-less transducer. Adopt the interface of human-machine and PLC programmable controller, it can synchronize accurately.

3.Mould is located by locating groove which makes it easy to change mould. The machine heats the PVC through conduction and forms it through pressing and frothing.

| Model: | LD-SW800 |

|---|---|

| MOQ: | 1 set |

| Payment: | L/C,T/T |

| Place of Origin: | China |

| Brand: | LEAD |

| Delivery Time: | 7 - 20 days |

4.The material is fed automatically. The mould and feeder can be designed as user's requirements.

5. The heating moulds will automatically separate when the machine stops, which contributes to protect the material between them and extend the machine's life.

6.Stepping motor drives and tow materials.

7.Adopt the equipment of trace pressing, batch number printing and scarp-collecting.

8. The print plate can be customerd as needed. You advise us the print picture, and we will response for the design and make for the plate.

9. The capacity can be 100-200 pcs per hour, and can meet large request for the chopsticks.

10. With the operation screen, it is easy for customer to operate the machine.

11.Travel scope can be adjusted.

Better connections, better business

Mobile/Whatsapp/WeChat